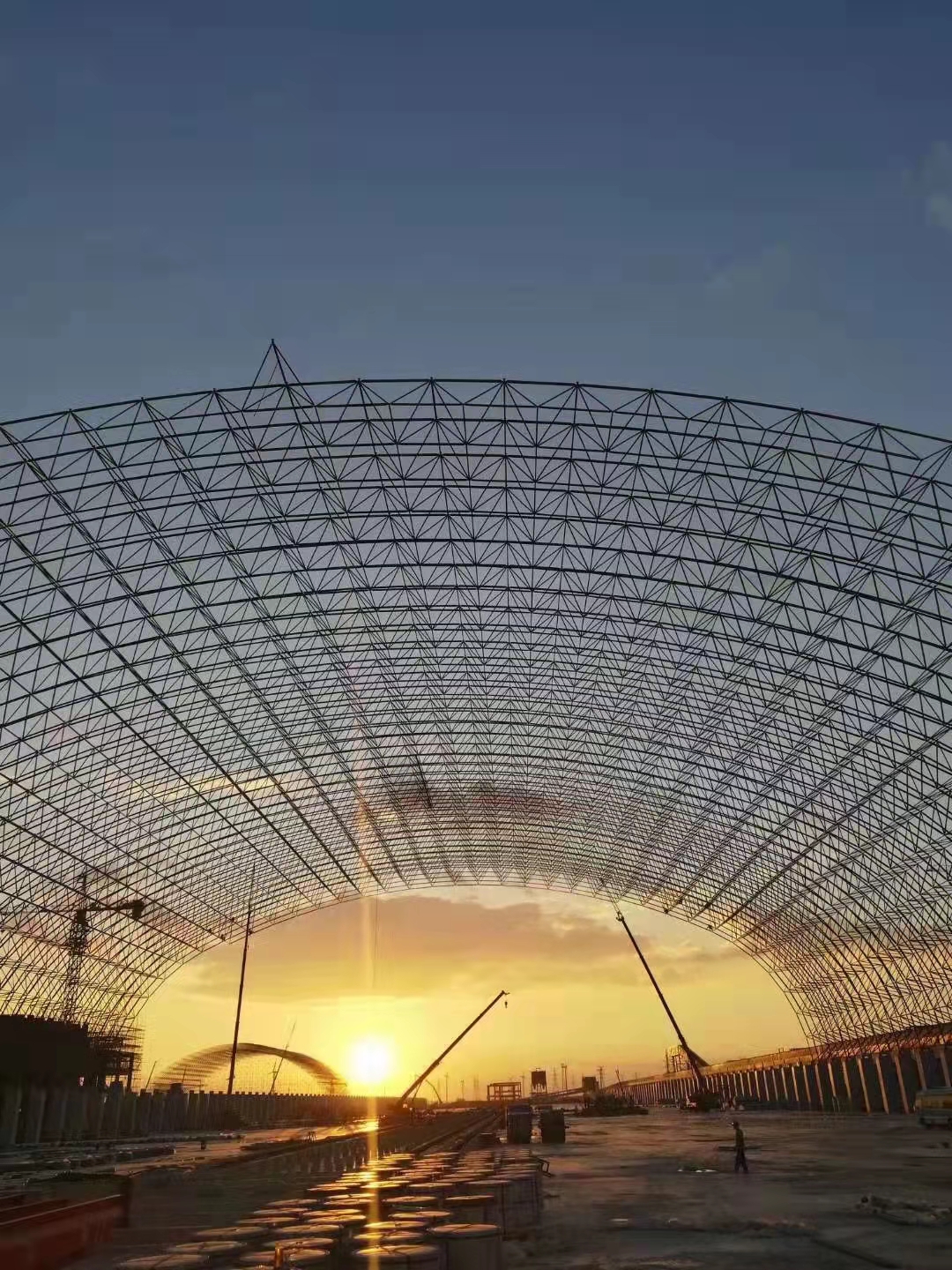

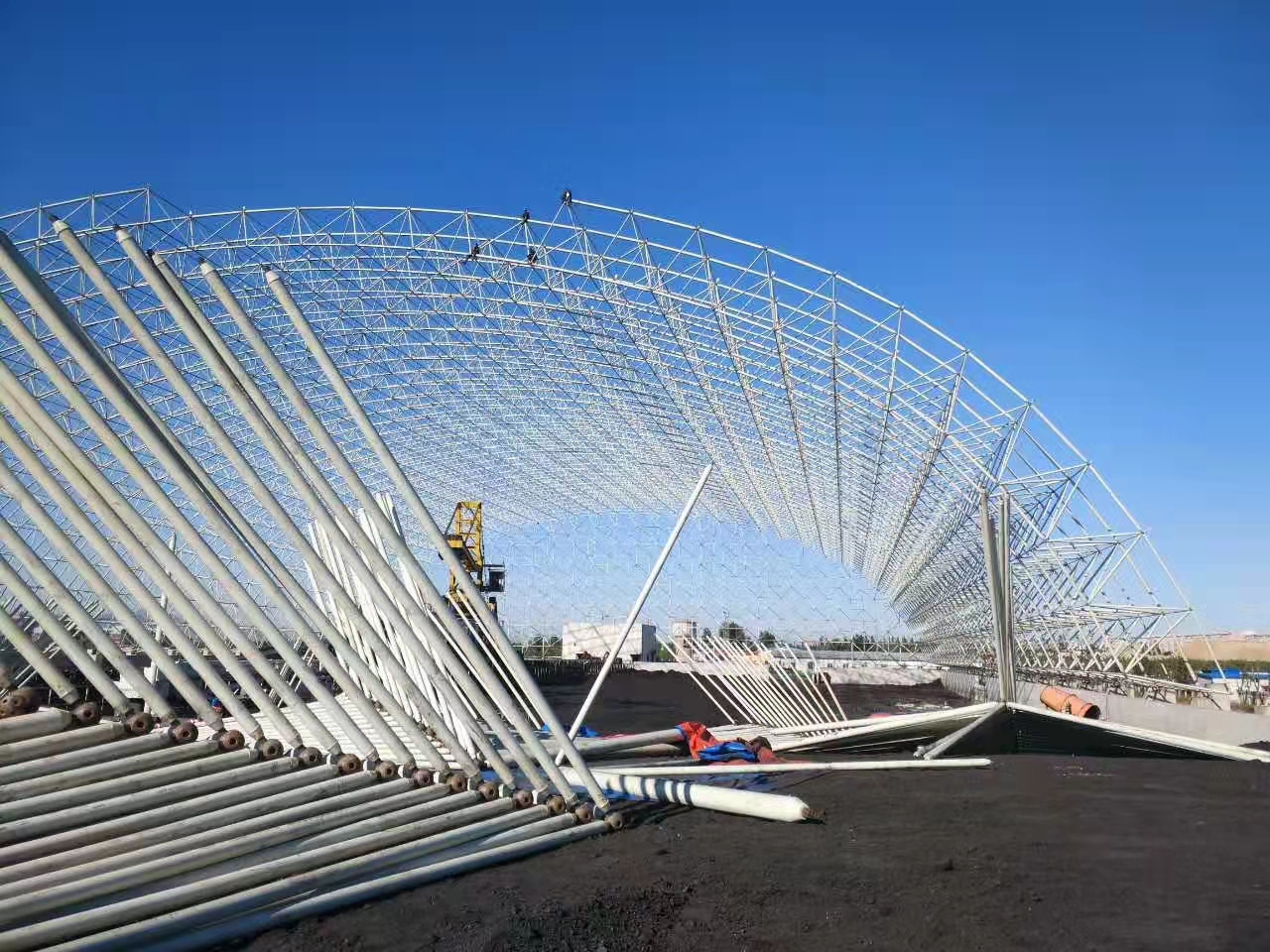

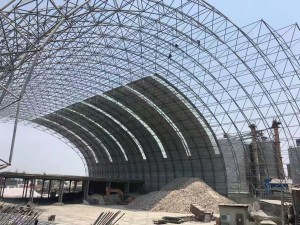

Ordos matenthedwe mphamvu chomera theka-zozungulira zitsulo kapangidwe danga chimango

Zopangira Q235B welded chitoliro / Kutalika konse ndi 49 metres / Kutalika konse ndi 96 metres / Kutalika konse ndi 567 metres.

1. Kusankhidwa kwa zinthu kuyenera kukhazikitsidwa pa ziphaso za discretionary quality ndi malipoti obwerezanso, mogwirizana ndi miyezo yamakono ya dziko.

2. Chitoliro chachitsulo chimatenga chitsulo cha Q355B, chitoliro chopanda chitsulo chosasunthika kapena chitoliro chokwera pafupipafupi (GB / T 700).

3. Maboti amphamvu kwambiri amapangidwa ndi 40Cr kuzimitsidwa ndi kutenthedwa ndi kutentha molingana ndi "Technical Conditions for High-Quality Carbon Structural Steel Structures" GB/T 16939. Kuchita kwa diameter

4. Mipira yachitsulo imapangidwa ndi zida zachitsulo za 45 zomwe zimagwirizana ndi "Technical Conditions for High-Quality Carbon Structural Steel" GB 699, ndi mphamvu zokolola za 360N / mm2.

5. Chosindikizira chosindikizira cha mutu wa cone chimapangidwa ndi chitsulo cha Q355B, ndipo mutu wa cone umapangidwa ndi forgings.

6. Mtedza wopanda ulusi umapangidwa ndi zida zachitsulo za Q355B.Pamene kukula kwa mabawuti amphamvu kwambiri ndi> M30, gwiritsani ntchito zitsulo zopanga zitsulo 45-gauge.

7. Zomangira zomangirira zimapangidwa ndi 40Cr zomwe zazimitsidwa ndi kutenthedwa.

8. Thandizo limapangidwa ndi chitsulo cha Q355B, ndipo chothandiziracho chimapangidwa ndi chitsulo cha Q235B

9. Elekitirodi utenga E43XX mndandanda;E50XX mndandanda (wowotcherera wa bawuti mpira ndi kubala nthiti)

10. Ma purlins amapangidwa ndi chitsulo chofanana ndi Q235B C.

11. Mabotolo wamba amapangidwa ndi kalasi C yazitsulo zowonongeka zopangidwa ndi zitsulo za Q235B zomwe zimakwaniritsa zofunikira za dziko lino, ndipo gawo la ntchito ndi 4.8.

12. Ma electrode owotcherera ndi mawaya omwe amagwiritsidwa ntchito powotcherera amayenera kukwaniritsa zofunikira pamiyezo yapadziko lonse lapansi.Kuwotcherera pakati pa zitsulo za Q235B kutengera maelekitirodi a E43, ndipo kuwotcherera pakati pa zitsulo za Q345B kutengera maelekitirodi a E50.

13. Zopangira denga: Onani chithunzi cha denga la grid kuti mumve zambiri.

14. Kuwonjezera pa kukwaniritsa zofunikira za dziko, zitsulo zomwe zimagwiritsidwa ntchito mu polojekitiyi ziyeneranso kukwaniritsa zofunikira izi:

a) Chiŵerengero cha mtengo woyezedwa wa mphamvu ya zokolola za chitsulo ku mtengo woyezera wa mphamvu yachitsulo sichiyenera kukhala yaikulu kuposa 0,85;

b) Chitsulocho chiyenera kukhala ndi njira zowonetsera zokolola, ndipo elongation iyenera kukhala yaikulu kuposa 20%;

c) Chitsulocho chiyenera kukhala ndi weldability wabwino ndi oyenerera amakhudza kulimba;