chitsulo danga chimango blanking ndondomeko

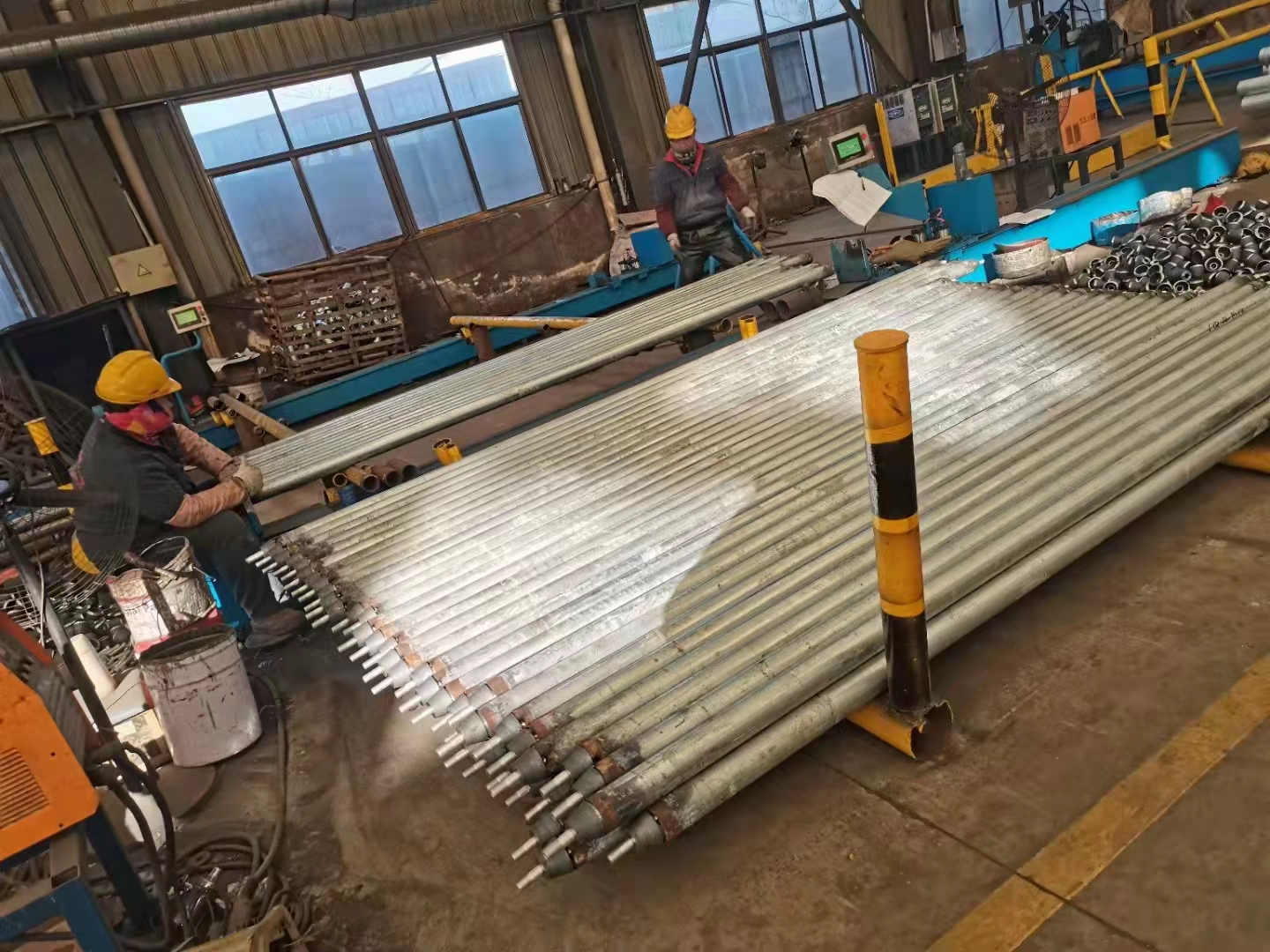

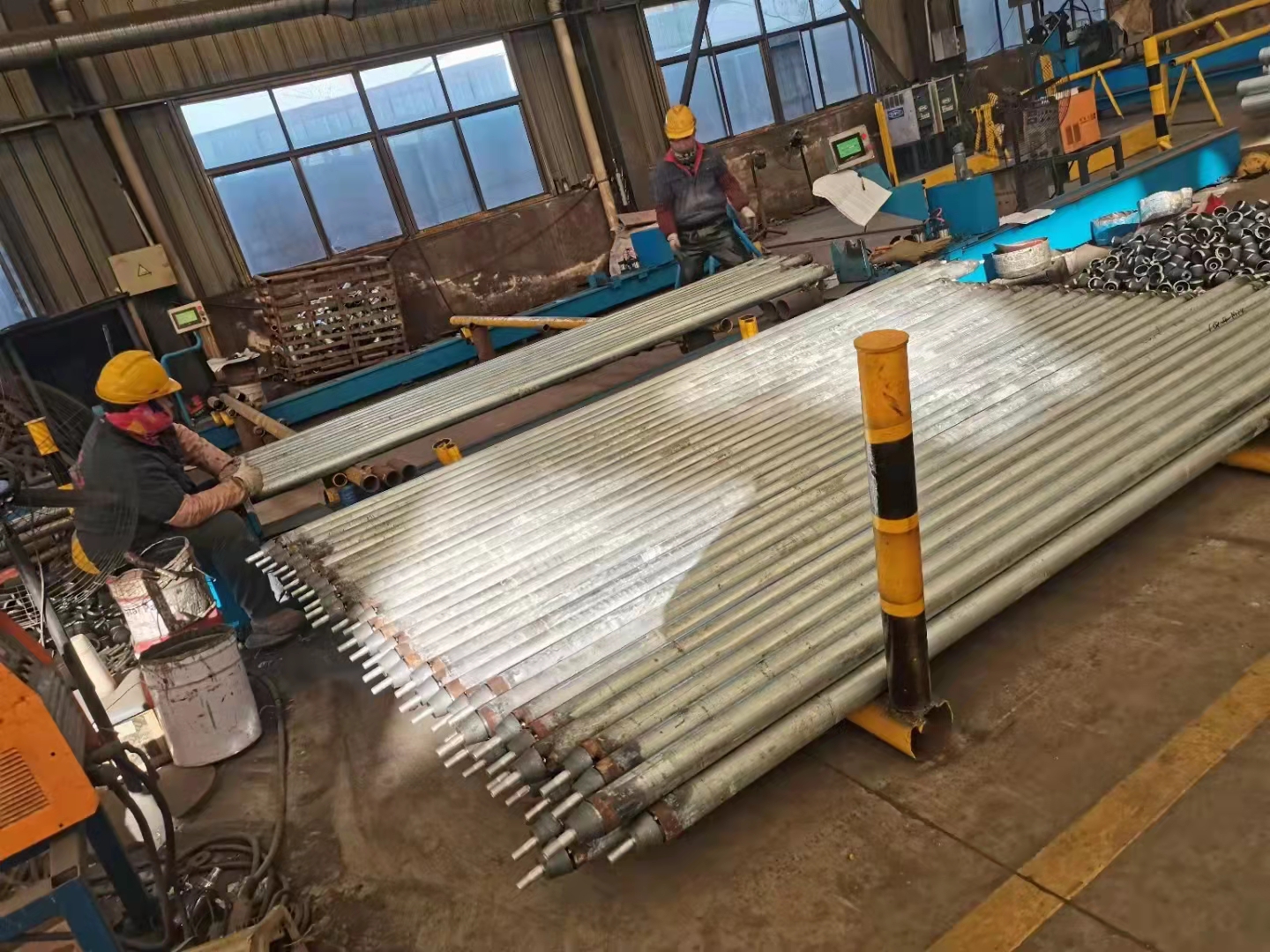

kudula:

A.Ogwira ntchito yomangayo ayenera kuyang'anitsitsa zojambulazo, ndipo ngati pali vuto lililonse, azikweza mwamsanga kwa katswiri wodziwa ntchito kuti apewe mavuto.

kuthetsa vutoli mu nthawi.

B. Kukula kwa ma node ofunikira kuyenera kudulidwa kapena kuwerengedwa.

C. Zida zoyezera zomwe zimagwiritsidwa ntchito popanga stakeout, blanking ndi chigawo chimodzi ndi kuyang'anitsitsa ziyenera kukhala zida zoyezera zoyenera zotsimikiziridwa ndi dipatimenti yoyezera ndi kuyesa.

D. Mzere wodulira kuti usatchule uyenera kukhala wolondola komanso womveka bwino, ndi chilolezo chowotcherera shrinkage ndi kukonza m'mphepete.

E. Kudula kwa magawo kuyenera kudulidwa ndi makina ometa ubweya, makina odula moto, makina ophatikizira nkhonya ndi kumeta ubweya, makina ocheka uta, ndi zina zotero, malingana ndi momwe zinthu zilili, ndi kudula kwamanja kuyenera kupewedwa momwe zingathere.Onani tebulo la kupatuka kovomerezeka kwa njira zosiyanasiyana zodulira ndi malo odulira

F. Ma nick am'deralo okhala ndi kuya kopitilira 1mm pamtunda wodulira, amadula ndikuya kupitilira 2mm, ndi otsalira.

Zotsalira zotsalira ziyenera kukonzedwa ndikupukutidwa.

| Kudula njira ndi chololeka kupatuka kwa kudula pamwamba | |

| Dzina la polojekiti | Kulekerera |

| Makina odzipangira okha ndi theka-automatic kudula | ± 1.5mm |

| The sanali perpendicular otsetsereka a kudula pamwamba ndi | ≤1.5mm |

| Kudula bevel angle | ±3° |

| Kudulira m'mphepete | ± 2.0mm |

| Kudula manja | ± 2.0mm |

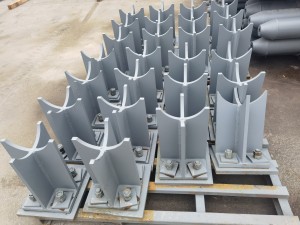

G. The kuwotcherera groove mawonekedwe a chigawo chimodzi ayenera kusankhidwa molingana ndi kuwotcherera chizindikiro chizindikiro pa chojambula ndi poyambira mawonekedwe ndi kukula.